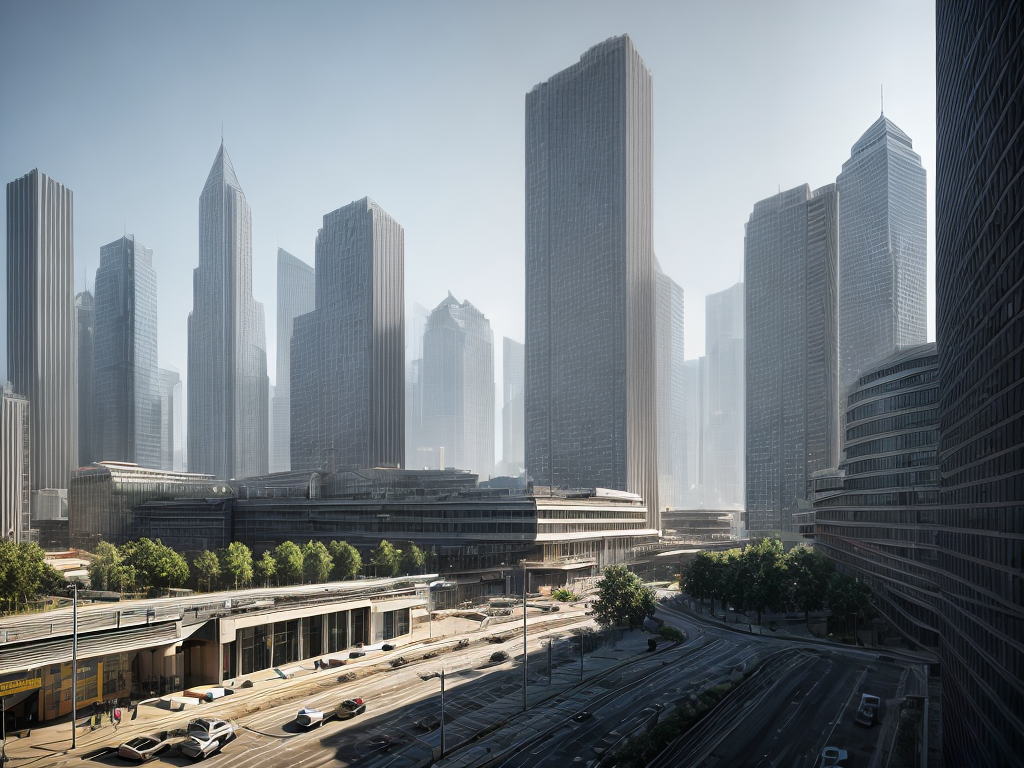

As I walked through the bustling streets of a modern metropolis, I couldn’t help but marvel at the towering skyscrapers that reached towards the sky, seemingly defying gravity. These structures, made possible by the evolution of concrete, stand as testaments to the ingenuity and innovation of humanity. From its humble beginnings as a basic mixture of cement, aggregate, and water, concrete has undergone a remarkable journey of transformation and improvement. But how exactly has this ubiquitous material evolved over time? Join me as we explore the fascinating story of concrete’s evolution, from early experimentation to cutting-edge advancements, and uncover how Universal’s journey through innovation has shaped the very foundations of our modern world.

Key Takeaways

- Ancient civilizations, such as the Egyptians and Romans, made significant contributions to the development of concrete by experimenting with different materials and techniques.

- The introduction of innovative concrete mixtures, like high-performance concrete and self-healing concrete, has greatly improved the strength, durability, and sustainability of concrete.

- Advancements in reinforcing materials, such as carbon fiber and fiber reinforced polymers, have enhanced the structural properties of concrete and increased its load-bearing capacity.

- The introduction of precast concrete has revolutionized the construction industry, offering a more efficient and cost-effective alternative to traditional methods, with improved quality control and architectural versatility.

Early Experimentation and Discovery

During my research on the evolution of concrete, I discovered that early experimentation and discovery played a crucial role in shaping its development. The journey of concrete began centuries ago, with ancient civilizations employing various early techniques to create rudimentary forms of the material. These early techniques laid the foundation for the historical discoveries that would transform concrete into the versatile substance we know today.

One notable early technique was the use of lime mortar by the ancient Egyptians. They discovered that by combining limestone and water, they could create a paste that hardened over time. This discovery revolutionized construction methods, allowing for the creation of more durable structures. Similarly, the Romans made significant advancements in concrete technology by incorporating volcanic ash, known as pozzolana, into their mixtures. This innovation resulted in a stronger and more resilient material, capable of withstanding the test of time.

As time progressed, more historical discoveries were made, leading to further enhancements in concrete. In the 18th century, John Smeaton, an English engineer, experimented with various mixtures and discovered that adding a blend of clay and limestone to the concrete mixture greatly increased its strength. This finding marked a significant milestone in the evolution of concrete, as it provided a scientific basis for its composition and opened doors for further experimentation and improvement.

The early techniques and historical discoveries surrounding concrete were instrumental in its development. They laid the groundwork for future innovations and advancements in construction materials. Without the curiosity and ingenuity of those early pioneers, the concrete structures we see today would not exist. It is through their relentless pursuit of knowledge and their willingness to experiment that we have been able to harness the incredible potential of concrete in modern-day construction.

Innovative Concrete Mixtures

As we explore the topic of innovative concrete mixtures, it is important to highlight the advancements in new material compositions and their impact on enhancing structural properties. These mixtures have revolutionized the construction industry by offering improved durability, strength, and flexibility. By incorporating innovative ingredients and refining the proportions, engineers and researchers have pushed the boundaries of what concrete can achieve, paving the way for safer and more efficient structures.

New Material Compositions

Concrete’s evolution has been marked by the constant exploration and development of new material compositions, resulting in innovative concrete mixtures that push the boundaries of what this versatile building material can achieve. Today, new material innovations and experimental mixtures are revolutionizing the construction industry. One such innovation is the use of high-performance concrete (HPC), which incorporates advanced admixtures and fibers to enhance strength, durability, and flexibility. HPC allows for the creation of thinner and lighter structures without compromising on structural integrity. Another breakthrough is the development of self-healing concrete, which contains capsules filled with healing agents that can repair cracks autonomously, prolonging the lifespan of concrete structures. Additionally, the use of recycled materials such as fly ash and slag has gained popularity, reducing waste and environmental impact. These new material compositions are transforming the possibilities of concrete, enabling architects and engineers to create structures that are stronger, more sustainable, and aesthetically pleasing.

Enhanced Structural Properties

One of the key advancements in the evolution of concrete is the development of innovative mixtures that enhance its structural properties. These new mixtures have led to improved durability and enhanced load bearing capacity, making concrete a more reliable and versatile building material. The improved durability of these innovative mixtures ensures that concrete structures can withstand harsh weather conditions, chemical exposure, and wear and tear over time. Additionally, the enhanced load bearing capacity allows concrete to support heavier loads, making it suitable for a wide range of construction projects, from bridges to high-rise buildings. These advancements in concrete technology have revolutionized the construction industry, providing engineers and architects with more options and possibilities in their designs. With these innovative mixtures, concrete continues to evolve and meet the ever-increasing demands of modern construction.

Advancements in Reinforcing Materials

Over the years, the evolution of concrete has led to significant advancements in the materials used for reinforcing its strength and durability. As an audience seeking mastery, it is important to understand the latest developments in reinforcing materials. Here are some key advancements in this field:

-

Carbon Fiber: Carbon fiber has emerged as a popular choice for reinforcing concrete due to its exceptional strength-to-weight ratio. It is incredibly lightweight, yet stronger than steel, making it an ideal material for reinforcing structures. Carbon fiber reinforcements are corrosion-resistant and have high tensile strength, allowing for better load-bearing capacity and improved structural integrity.

-

Fiber Reinforced Polymers (FRP): FRPs are composite materials that consist of fibers embedded in a polymer matrix. These fibers, commonly made of glass, carbon, or aramid, provide additional strength and stiffness to the concrete. FRPs exhibit excellent resistance to corrosion, making them suitable for reinforcing structures in aggressive environments. Moreover, their flexibility allows for easy installation and retrofitting.

-

Improved Bonding Agents: Advances have been made in developing effective bonding agents for reinforcing materials. These agents ensure strong adhesion between the reinforcing material and the concrete matrix, enhancing the overall structural performance. With improved bonding, the reinforced concrete can withstand higher loads and resist cracking, improving its durability.

-

Innovative Reinforcement Techniques: Innovations in reinforcing techniques have also contributed to the evolution of concrete. For instance, researchers have developed methods to integrate reinforcing materials directly into the concrete mix, resulting in a homogenous composite with enhanced strength and durability. Additionally, automated manufacturing processes have improved the consistency and quality of reinforcing materials, ensuring their optimal performance.

Introduction of Precast Concrete

As a concrete enthusiast, I am excited to delve into the introduction of precast concrete and its impact on the industry. Precast construction has revolutionized the way buildings are constructed, offering a more efficient and cost-effective alternative to traditional methods. With precast concrete, components are manufactured off-site in a controlled environment, allowing for higher quality and precision in the production process.

One of the key advantages of precast construction is its ability to enable modular building. This means that different building components, such as walls, floors, and columns, can be precast and then assembled on-site like building blocks. This not only speeds up the construction process but also allows for greater flexibility in design and customization.

The introduction of precast concrete has had a significant impact on the construction industry. It has helped to reduce construction time and costs, as the precast components can be fabricated concurrently with site preparation, thereby minimizing on-site labor and material waste. Additionally, the controlled environment in which precast components are manufactured ensures consistent quality, resulting in structurally sound and durable buildings.

Furthermore, precast construction offers environmental benefits. The off-site manufacturing process reduces noise, dust, and pollution at the construction site, making it more sustainable and less disruptive to the surrounding environment. Additionally, the durability and energy efficiency of precast concrete buildings contribute to reduced maintenance and operational costs over their lifespan.

Development of High-Strength Concrete

After exploring the introduction of precast concrete and its impact on the construction industry, it is now time to shift our focus to the development of high-strength concrete. High-strength concrete is a remarkable innovation that has revolutionized the field of construction. It offers several benefits over traditional concrete, such as increased load-bearing capacity and improved durability. Let’s delve into the details of this fascinating development:

-

High Performance Additives: High-strength concrete is achieved by incorporating high performance additives into the mix. These additives can include silica fume, fly ash, and superplasticizers. Silica fume, a byproduct of silicon metal production, enhances the strength and durability of the concrete. Fly ash, a residue from coal combustion, improves workability and reduces permeability. Superplasticizers, on the other hand, improve the fluidity of the mix without compromising its strength.

-

Durability Enhancements: High-strength concrete exhibits superior durability compared to conventional concrete. It is more resistant to cracking, weathering, and chemical attacks. This makes it suitable for a wide range of applications, including high-rise buildings, bridges, and infrastructure projects. The enhanced durability of high-strength concrete ensures that structures built with it have a longer service life and require less maintenance.

-

Structural Efficiency: High-strength concrete allows for the design of slimmer and lighter structures without compromising their strength and stability. This results in cost savings and increased design flexibility. The higher compressive strength of the material also enables the construction of taller buildings, reducing the need for excessive reinforcement.

-

Sustainable Construction: The use of high-strength concrete can contribute to sustainable construction practices. By utilizing high performance additives, it is possible to reduce the amount of cement required in the mix, thereby reducing carbon emissions. Additionally, the longer lifespan and reduced maintenance needs of structures built with high-strength concrete contribute to a more sustainable built environment.

The development of high-strength concrete has undoubtedly transformed the construction industry. Its combination of high performance additives and durability enhancements has opened up new possibilities in architectural design and engineering. As we continue to innovate in the field of concrete technology, high-strength concrete will undoubtedly play a crucial role in shaping the future of construction.

Application of Sustainable Practices

Sustainable practices play a crucial role in promoting environmentally conscious construction methods and reducing the carbon footprint of the construction industry. As the demand for more eco-friendly buildings increases, it becomes imperative to adopt sustainable construction methods and use eco-friendly materials. These practices not only benefit the environment but also contribute to energy efficiency and long-term cost savings.

One key aspect of sustainable construction methods is the use of renewable energy sources. Incorporating solar panels or wind turbines into building designs can help reduce the reliance on fossil fuels and decrease greenhouse gas emissions. Additionally, energy-efficient lighting systems, heating, ventilation, and air conditioning (HVAC) systems can significantly reduce energy consumption.

Another important consideration is the use of eco-friendly materials. Traditional concrete production contributes to high greenhouse gas emissions due to the production of cement. However, advancements in concrete technology have led to the development of eco-friendly alternatives. These alternatives use supplementary cementitious materials such as fly ash, slag, or silica fume, which have a lower carbon footprint. Additionally, incorporating recycled materials like crushed concrete or reclaimed aggregates can reduce the demand for virgin resources and minimize waste.

Furthermore, sustainable construction practices also involve optimizing water usage. Implementing water-saving fixtures, such as low-flow toilets and faucets, can significantly reduce water consumption. Additionally, the use of rainwater harvesting systems can help mitigate the strain on local water resources.

Utilizing Technology for Improved Production

Technology plays a crucial role in improving production efficiency in the concrete industry. By embracing automation and integrating advanced manufacturing techniques, companies can achieve higher productivity levels. The advancements in technology have revolutionized the way concrete is manufactured, leading to faster and more precise production processes.

Technology’s Role in Efficiency

By incorporating advanced machinery and digital systems, Universal has revolutionized its production process, enhancing efficiency and streamlining concrete manufacturing. Through improved construction techniques and efficiency through automation, Universal has achieved significant advancements in its operations. Here are some of the ways technology has played a crucial role in enhancing efficiency:

- Implementation of automated batching systems, ensuring accurate and consistent mixing of concrete ingredients.

- Utilization of advanced robotics in the production line, reducing manual labor and increasing productivity.

- Integration of real-time monitoring systems to track production progress and identify potential issues in real-time.

- Adoption of digital modeling and simulation tools, allowing for better planning and optimization of resources.

With these technological advancements, Universal has not only improved the efficiency of its concrete manufacturing but also set new benchmarks for the industry.

Automation for Higher Productivity

As the advancements in technology continue to shape the efficiency of concrete manufacturing, automation emerges as a key driver for higher productivity at Universal. Automation in construction has revolutionized the way we produce concrete, leading to numerous benefits in terms of speed, accuracy, and cost-effectiveness. By incorporating technology into our production processes, we have been able to streamline operations and reduce manual labor, resulting in increased productivity and improved overall efficiency. Automated systems allow for precise measurement and mixing of ingredients, ensuring consistent quality in every batch of concrete produced. Additionally, automation enables faster production cycles, reducing project timelines and allowing for quicker completion of construction projects. The benefits of technology in concrete production are undeniable, and at Universal, we are committed to embracing automation to further enhance our productivity and deliver superior results to our clients.

Advancements in Manufacturing

With advancements in manufacturing, we have harnessed the power of technology to significantly improve production processes at Universal. The integration of smart manufacturing and automation in production has revolutionized our operations, allowing us to achieve higher levels of efficiency, accuracy, and consistency. Here are some key advancements that have transformed our manufacturing capabilities:

- Robotics and Artificial Intelligence: We have implemented robotic systems that can perform repetitive tasks with precision and speed, reducing human error and increasing productivity.

- Internet of Things (IoT): Our machinery and equipment are now interconnected through IoT, enabling real-time data collection, analysis, and optimization of production processes.

- 3D Printing: Additive manufacturing has enabled us to create complex structures and components with greater flexibility and reduced waste.

- Virtual Reality (VR) and Augmented Reality (AR): These technologies have enhanced our design and prototyping processes, allowing for better visualization and collaboration.

Through these advancements in manufacturing, we have streamlined our operations, improved product quality, and elevated our overall efficiency to meet the demands of a rapidly evolving industry.

Enhancing Durability and Longevity

Through continuous research and development, Universal has successfully extended the durability and longevity of concrete, ensuring its resilience in various environments. One of the key aspects of enhancing durability is corrosion prevention. Concrete structures are often exposed to harsh elements, such as saltwater or chemicals, which can lead to corrosion of the reinforcement bars. To combat this issue, Universal has developed innovative corrosion prevention techniques that significantly increase the lifespan of concrete structures.

One approach Universal has taken is the use of eco-friendly additives. These additives not only enhance the strength and durability of concrete but also act as a barrier against corrosion. By incorporating these eco-friendly additives into the concrete mixture, Universal has been able to create structures that are more resistant to the effects of corrosion.

Furthermore, Universal has implemented advanced quality control measures to ensure the longevity of concrete structures. Through rigorous testing and monitoring, any potential weaknesses or vulnerabilities in the concrete are identified and addressed before they become major issues. This proactive approach allows Universal to provide customers with concrete structures that can withstand the test of time.

In addition to corrosion prevention measures, Universal also focuses on enhancing the overall durability of concrete. This includes optimizing the mix design, using high-quality materials, and implementing innovative construction techniques. By constantly seeking improvements in these areas, Universal is able to create concrete structures that are not only durable but also highly resilient in various environments.

Exploring New Forms and Structures

I’m excited to explore the realm of innovative concrete designs that push the boundaries of traditional structures. From intricate patterns to complex shapes, architects and engineers are finding new ways to utilize concrete in stunning and unconventional ways. With advancements in technology, we can now create stronger and more durable concrete structures that were once thought impossible. Let’s dive into the endless possibilities of concrete and witness the evolution of its forms and structures.

Innovative Concrete Designs

In my journey of exploring innovative concrete designs, I have witnessed the emergence of new forms and structures that push the boundaries of what was once thought possible. The evolution of concrete has opened up a realm of possibilities in sustainable construction methods. Here are some of the exciting new developments:

- Ultra-high-performance concrete (UHPC): This innovative material boasts exceptional strength and durability, allowing for thinner and lighter structures.

- 3D-printed concrete: With the advent of 3D printing technology, complex and intricate concrete structures can now be created with precision and efficiency.

- Self-healing concrete: Through the incorporation of special additives, concrete can now repair small cracks and imperfections by itself, increasing its lifespan and reducing maintenance costs.

- Biomimetic concrete: Taking inspiration from nature, biomimetic concrete mimics the self-healing properties of certain organisms, improving its resilience and sustainability.

The world of innovative concrete designs continues to evolve, driving the construction industry towards a more sustainable and efficient future.

Structural Advancements in Concrete

As I delve into the realm of structural advancements in concrete, innovative new forms and structures emerge, pushing the boundaries of what was once thought possible. In the quest for structural durability, engineers and architects are exploring eco-friendly solutions that not only enhance the strength of concrete but also reduce its environmental impact. One such advancement is the use of fiber-reinforced concrete, which incorporates fibers such as steel, glass, or synthetic materials to improve its tensile strength and resistance to cracking. Another innovative approach involves the development of self-healing concrete, which uses bacteria or capsules filled with healing agents to repair cracks autonomously. Additionally, the adoption of sustainable aggregates, such as recycled materials or low-carbon options, contributes to reducing the carbon footprint of concrete structures. These structural advancements in concrete not only provide enhanced durability but also contribute to a more sustainable and eco-friendly built environment.

Exploring Concrete Possibilities

With each new structural advancement in concrete, the possibilities for exploring innovative new forms and structures expand, pushing the boundaries of what was once thought possible. As we continue to uncover the full potential of this versatile material, we are discovering exciting new applications and sustainable construction techniques. Here are some of the ways we are exploring concrete possibilities:

- Geometric Freedom: Concrete’s adaptability allows us to create complex, unconventional shapes that were previously unattainable, opening up endless design possibilities.

- Smart Concrete: By incorporating sensors and actuators into concrete structures, we can create intelligent infrastructure that can monitor its own health and respond to external stimuli.

- Green Concrete: We are constantly developing eco-friendly alternatives to traditional concrete, such as using recycled materials or integrating self-healing properties to reduce maintenance needs.

- Lightweight Concrete: By using lightweight aggregates or incorporating air voids, we can create concrete structures that are not only strong but also significantly lighter, reducing material consumption and transportation costs.

As we delve into these new frontiers of concrete exploration, we are paving the way for a more sustainable and innovative future in construction.

Revolutionizing Concrete Finishes

Over the years, Universal has transformed concrete finishes with innovative techniques and cutting-edge technology. We have revolutionized concrete aesthetics by pushing the boundaries of what is possible with this versatile material. Our commitment to sustainable concrete practices has also played a crucial role in shaping the future of concrete finishes.

One of the ways we have revolutionized concrete aesthetics is by introducing a wide range of finishes that enhance the visual appeal of concrete surfaces. From polished concrete to exposed aggregate finishes, we have developed techniques that bring out the natural beauty of concrete while providing durability and longevity. Our team of experts continuously experiments with new materials and processes to create unique textures and patterns that elevate the overall design of any space.

In addition to revolutionizing the visual aspect of concrete finishes, we have also prioritized sustainable concrete practices. We understand the importance of reducing the environmental impact of construction materials, and concrete is no exception. Through extensive research and development, we have implemented innovative methods to reduce carbon emissions during the production of concrete finishes. Our commitment to sustainability extends beyond the manufacturing process, as we also prioritize the use of recycled materials and minimize waste throughout our operations.

Pushing the Boundaries of Design

I have continuously pushed the boundaries of design in order to innovate and elevate the possibilities of concrete finishes. By exploring new techniques and materials, I have been able to push the limits of what is traditionally thought possible with concrete. Here are some of the innovative applications that have emerged as a result:

-

Textured Surfaces: I have developed techniques to create intricate and unique textures on concrete surfaces, allowing for a wide range of design possibilities. From smooth and polished finishes to rough and rugged textures, these surfaces add depth and character to any space.

-

Color Variations: Through extensive research and experimentation, I have discovered ways to achieve a wide spectrum of colors in concrete. From vibrant hues to subtle shades, these innovative applications of color allow for endless design possibilities, enabling architects and designers to create truly bespoke spaces.

-

Lightweight Concrete: By incorporating lightweight aggregates into the mix, I have been able to create concrete that is not only strong and durable but also significantly lighter than traditional concrete. This opens up a whole new realm of design possibilities, as it allows for larger and more intricate structures to be built with ease.

-

3D Printing: Pushing the boundaries of design even further, I have been exploring the use of 3D printing technology in concrete construction. This innovative application allows for the creation of complex and intricate structures that were previously thought impossible to achieve with traditional construction methods.

Through these innovative applications, I continue to push the boundaries of design and explore the endless possibilities of concrete finishes. By pushing the limits of what can be achieved, I am able to create truly unique and inspiring spaces that showcase the versatility and beauty of concrete.

Innovations in Concrete Transportation and Placement

Continuing the exploration of concrete’s endless possibilities, we now venture into the realm of innovations in concrete transportation and placement. In the world of construction, transportation efficiency and placement techniques play a crucial role in ensuring that concrete is delivered and placed accurately and efficiently.

To improve transportation efficiency, advancements have been made in the design and engineering of concrete transportation vehicles. One notable innovation is the development of self-loading concrete mixers. These mixers are equipped with a rotating drum that can mix the concrete while in transit, eliminating the need for a separate mixing station. This not only saves time and labor but also reduces the risk of concrete setting before it reaches the construction site.

Placement techniques have also seen significant advancements. One such innovation is the introduction of pump systems. Concrete pumps are hydraulic machines that are used to transport liquid concrete from the mixer to the desired location. These pumps can reach great heights and distances, allowing for precise and efficient placement of concrete, even in hard-to-reach areas. Additionally, the use of pump systems reduces manual labor and increases productivity on construction sites.

Another notable advancement in placement techniques is the use of laser-guided screeds. These devices use laser technology to level and smooth freshly poured concrete. By ensuring a level surface, laser-guided screeds eliminate the need for manual leveling, reducing labor costs and improving the overall quality of the finished product.

Improving Fire Resistance and Safety Measures

Advancements in fire resistance and safety measures have revolutionized the construction industry, ensuring the protection of structures and the well-being of those within. As the demand for safer and more sustainable solutions continues to grow, innovative technologies and eco-friendly innovations have emerged to address these concerns. Here are some of the key improvements in fire resistance and safety measures:

-

Fire-resistant coatings: The development of fire-resistant coatings has played a crucial role in enhancing the fire resistance of structures. These coatings are applied to concrete surfaces, forming a protective barrier that slows down the spread of flames and reduces the release of toxic gases.

-

Intumescent materials: Intumescent materials are substances that expand when exposed to high temperatures, forming a char layer that insulates the underlying structure. These materials are commonly used in the construction of fire-resistant doors and partitions, providing additional time for evacuation during emergencies.

-

Smoke control systems: Smoke control systems play a vital role in improving safety by managing the movement of smoke within a building. These systems are designed to prevent the spread of smoke to other areas, ensuring safe evacuation routes and minimizing the risk of smoke inhalation.

-

Fire-resistant structural elements: Innovations in concrete design and construction techniques have led to the development of fire-resistant structural elements. These elements are designed to withstand high temperatures and maintain their structural integrity during fires, ensuring the safety of the building and its occupants.

With these advancements in fire resistance and safety measures, the construction industry is moving towards a future where structures are better equipped to withstand fires and protect lives. By embracing sustainable solutions and eco-friendly innovations, we can build a safer and more resilient world.

Addressing Environmental Concerns

With the growing focus on sustainability and environmental consciousness, the construction industry has turned its attention towards addressing the environmental concerns associated with concrete production and usage. As a leading company in the industry, Universal is committed to incorporating green building practices and reducing the carbon footprint of our concrete products.

One of the key ways we address these concerns is through the use of alternative materials in concrete production. By replacing a portion of the traditional Portland cement with supplementary cementitious materials such as fly ash or slag, we can reduce the amount of carbon dioxide emitted during the manufacturing process. These materials not only utilize waste products that would otherwise end up in landfills, but they also require less energy to produce, further reducing our environmental impact.

Additionally, Universal is focused on improving the durability and longevity of our concrete products. By investing in research and development, we aim to create concrete that requires less maintenance and replacement over time. This not only reduces the amount of materials needed for repairs but also minimizes the carbon emissions associated with the production and transportation of new materials.

Furthermore, we are actively involved in promoting sustainable construction practices by educating builders, architects, and engineers about the benefits of green building. We provide resources and guidance on incorporating environmentally friendly practices throughout the construction process, from design to completion.

Future Prospects and Ongoing Research

As we look towards the future of concrete, there are several key areas that deserve attention. Innovations in concrete technology are continuously being explored, paving the way for stronger and more durable construction materials. Advancements in sustainable concrete are also a priority, as we seek to minimize the environmental impact of this widely used material. Additionally, emerging concrete construction techniques are being researched and developed to enhance efficiency and productivity in the industry.

Innovations in Concrete Technology

My journey through the world of concrete technology has shown me the exciting future prospects and ongoing research that promise to revolutionize the industry. Here are some of the current innovations and advancements in concrete technology:

-

Precast Innovations: The use of precast concrete elements has gained popularity due to its numerous advantages, such as improved quality control, faster construction time, and reduced labor costs. Innovations in precast technology include the development of high-performance precast elements, such as lightweight and ultra-high strength concrete, which offer increased structural efficiency and design flexibility.

-

Eco-Friendly Solutions: With a growing focus on sustainability, researchers are actively exploring eco-friendly alternatives to traditional concrete. This includes the use of recycled materials such as fly ash, slag, and silica fume as partial replacements for cement, reducing carbon dioxide emissions. Additionally, the development of self-healing and self-cleaning concrete formulations aims to enhance durability while reducing maintenance requirements.

-

Advanced Concrete Mixtures: Ongoing research is focused on developing new concrete mixtures with improved properties, including enhanced strength, durability, and resistance to environmental factors. This includes the integration of nanotechnology and the use of chemical admixtures to optimize concrete performance and address specific application requirements.

-

Digitalization and Automation: The construction industry is embracing digitalization and automation, and concrete technology is no exception. From the use of advanced software for design and simulation to the implementation of robotic systems for concrete placement and finishing, these technologies promise to increase efficiency, precision, and productivity in concrete construction.

These innovations and ongoing research efforts demonstrate the exciting potential for the future of concrete technology, paving the way for sustainable and high-performance solutions in the industry.

Advancements in Sustainable Concrete

Researchers and industry professionals are actively exploring future prospects and conducting ongoing research to advance sustainable concrete technology. As the demand for sustainable construction practices continues to rise, there is an urgent need for eco-friendly concrete alternatives. Innovations in sustainable concrete aim to reduce the environmental impact of traditional concrete production, which is known for its high carbon emissions. One promising approach is the use of supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume, which can replace a portion of cement in concrete. These materials not only reduce carbon dioxide emissions but also enhance the durability and strength of the concrete. Additionally, researchers are investigating the use of recycled aggregates as a replacement for natural aggregates, further reducing the environmental footprint of concrete production. Ongoing research efforts are focused on optimizing the mix design, improving the durability, and exploring new materials and technologies to enhance the sustainability of concrete.

Emerging Concrete Construction Techniques

Building upon the advancements in sustainable concrete, the exploration of emerging concrete construction techniques is paving the way for future prospects and ongoing research in the field. As we continue to push the boundaries of what is possible with concrete, new techniques are being developed that prioritize sustainability while maintaining structural integrity. Here are some of the emerging construction techniques that hold promise for the future:

- 3D printing: Using additive manufacturing techniques to create complex concrete structures with minimal waste.

- Self-healing concrete: Incorporating microorganisms or capsules in the concrete mix to repair cracks and increase durability.

- Carbon capture and utilization: Capturing carbon dioxide emissions from concrete production and using them to create new materials.

- Smart concrete: Embedding sensors and actuators in the concrete to monitor structural health and optimize performance.

These emerging techniques not only promote sustainable practices but also open doors to innovative and efficient construction methods. The future of concrete construction looks promising, with ongoing research and advancements in these areas.

Conclusion

In conclusion, the evolution of concrete has been a journey filled with innovation and progress. Like a phoenix rising from the ashes, concrete has continuously adapted and improved over time, becoming stronger, more versatile, and more sustainable. With advancements in materials, transportation, and safety measures, it has become a reliable and essential building material. As we look to the future, ongoing research and development will continue to shape the concrete industry, paving the way for even greater possibilities.